Knowledge

Rail Transit Fiber Infrastructure: Vibration Resistance & Signaling 2025

Rail transit fiber infrastructure demonstrates strong growth in 2025, driven by digital transformation and urban expansion. Operators deploy fiber broadband and advanced fiber optics to address vibration resistance and signaling reliability. High-speed rail projects in Asia and Europe show rapid growth, supported by robust funding and broadband investments. Fiber broadband enables real-time monitoring and predictive maintenance, improving safety and operational efficiency. Integration with AI, IoT, and 5G/6G accelerates trends in automation and network optimization. The market’s growth reflects rising funding and adoption of rail transit fiber for modern rail systems.

Key Takeaways

Vibration-resistant cables, ultra-low loss fibers & AI maintenance ensure reliable rail transit fiber networks with 5G integration.

Rail transit fiber networks use strong, vibration-resistant cables and connectors to ensure safe and reliable data transmission in harsh environments.

Advanced fiber technologies like ultra-low loss and bend-insensitive fibers improve network performance and reduce maintenance needs.

Distributed fiber sensing helps detect track problems early, supporting real-time monitoring and predictive maintenance to boost safety.

AI-driven maintenance and 5G/6G integration are transforming rail fiber systems, making them smarter and more efficient.

Proactive vibration isolation, robust cybersecurity, and modular designs keep rail fiber networks resilient and ready for future growth.

Rail Transit Fiber Fundamentals

Covers fault tolerance, fiber components & EN 50155/TIA-568 standards for robust rail communication infrastructure.

System Requirements & Key Components

Rail transit fiber infrastructure forms the backbone of modern rail networks, supporting critical telecommunications and signaling functions. Operators rely on fiber-based core infrastructure to deliver high-speed, secure data transmission across stations, control centers, and trains. The system must meet several requirements to ensure reliability and safety in demanding rail environments.

Fault tolerance and network resilience allow the infrastructure to handle data transmission delays and maintain continuous operations.

Compliance with railway fire and smoke standards is mandatory for all fiber optic cabling and connectors.

Mechanical and environmental robustness is essential. Fiber components must resist vibration, seal against contaminants, and tolerate extreme temperatures.

Ruggedized connectors with RoHS-compliant plating provide durability and consistent performance.

Connectors support both legacy fieldbus systems and high-speed Ethernet, enabling smooth transitions to full-Ethernet trains.

Fiber optic cables offer higher speed and security than copper, making them the preferred choice for rail transit fiber networks.

Continuous fiber monitoring plays a vital role in maintaining operational continuity. Advanced monitoring systems detect accidental breaks and tampering instantly, supporting both dark and lit fibers over long distances. Rapid fault location reduces repair time, saving costs and minimizing downtime. Integrated cybersecurity measures protect the network from hacking and unauthorized access, ensuring safety-critical applications like collision prevention remain secure.

Critical Considerations and Requirements | |

|---|---|

Must comply with fire safety and environmental standards; use high-quality jackets like RADOX. | |

Cable Jacket Material | RADOX EM 104 enhances tensile strength, abrasion resistance, and chemical resistance. |

Fiber Optic Connectors | Require resistance to shock and vibration, low optical attenuation, and minimal signal loss. |

Connector Design | Prevents dust, scratches, and misalignment; includes strain relief to avoid fiber stress. |

Connector Technologies | Expanded beam for easy maintenance; butt joint for optimal optical performance. |

Connector Body Types | Circular or rectangular, based on proven railway standards. |

Inter-Vehicle Jumper Systems | Designed for dynamic stresses; require specialized cable construction and termination. |

System Design and Termination | Must withstand millions of cycles and environmental challenges for long service life. |

Technical Standards (EN 50155, TIA-568)

Rail transit fiber infrastructure must comply with strict technical standards to guarantee performance and safety. EN 50155 sets requirements for electronic equipment used on rolling stock, including vibration resistance, temperature tolerance, and electromagnetic compatibility. TIA-568 defines standards for structured cabling systems, ensuring consistent fiber optic performance and interoperability across telecommunications networks.

EN 50155 certification confirms that fiber optic components can withstand the harsh conditions found in rail environments. TIA-568 compliance ensures reliable data transmission and supports the integration of advanced signaling and telecommunications systems. Together, these standards help operators build robust, future-ready networks that support real-time monitoring, predictive maintenance, and enhanced safety.

Vibration & Environmental Resistance

ADSS cables, armored sheaths & EN50155 equipment protect against vibration, EMI & temperature extremes.

Trackside Cabling Solutions

Rail transit fiber infrastructure faces constant vibration and environmental stress along trackside routes. Train passage induces dynamic vibrations, with strain effects reaching ±85 με/s on railway bridges. These vibrations, combined with temperature variations and electromagnetic interference, challenge the durability of fiber cables. Operators select advanced materials and installation techniques to protect fiber from these hazards.

ADSS fiber cables, designed for self-support and lightweight construction, reduce mechanical stress on support structures. Water-blocking materials and aramid yarn provide tensile strength, while protective jackets shield fiber from moisture and UV exposure. Armoured cables, such as Double-Insulated Super Armoured Cable (DI-SAC), use steel-wire armor and fire-retardant sheaths for high mechanical protection. Recycled polymer cable routes and concrete ground-level troughing offer impact resistance and deter theft. Elevated troughing minimizes soil disturbance, and burying cables at sufficient depth with consolidated soil prevents mechanical damage.

Category | Materials / Techniques | Durability Benefits / Notes |

|---|---|---|

Armoured Cables | DI-SAC, steel-wire armor, fire-retardant sheaths | High mechanical protection, suitable for vandal-prone areas |

Cable Routes | Recycled polymer, concrete troughing, elevated troughing | Impact resistance, theft deterrence, minimal soil disturbance |

Installation Depth | Deep burial, consolidated soil | Prevents damage and theft |

Soil Protection | Sand backfill, extra sheathing | Shields fiber from sharp stones |

Installation Method | Ploughing, scratch-burying | Reduces exposure and risk |

Anti-Theft Measures | Metal clips, epoxy adhesive, anchoring | Deters theft and vandalism |

Fibre Installation | Flexible installation, easy maintenance |

Operators use blown fiber in composite ducts for flexible installation and maintenance, ensuring the transit fiber solution remains resilient over time.

Wayside Communication Reliability

Wayside communication systems must maintain reliability under extreme vibration and environmental conditions. Railway communication components comply with standards such as EN50155, EN50121, and EN45545. These systems endure constant vibration, temperature fluctuations, and electromagnetic interference. Rugged, military-grade equipment with fanless designs and CNC-machined aluminum chassis absorbs vibration and dissipates heat efficiently.

Device ports use lockable M12 connectors to prevent cable disconnections caused by vibration. Environmental stress screening (ESS) tests verify durability under temperature extremes and vibration. Power conditioning handles inconsistent power quality, while modular designs with UPS backup improve resilience in space-constrained, vibration-prone locations. Commercial off-the-shelf enterprise technologies enhance reliability and maintainability. Wayside and trackside equipment must resist metallic dust, moisture, electrical surges, and fire. Failure to meet these standards leads to service interruptions and shorter equipment lifespan.

Tip: Operators should prioritize robust fiber cabling and modular equipment to ensure uninterrupted wayside communication, even in harsh rail environments.

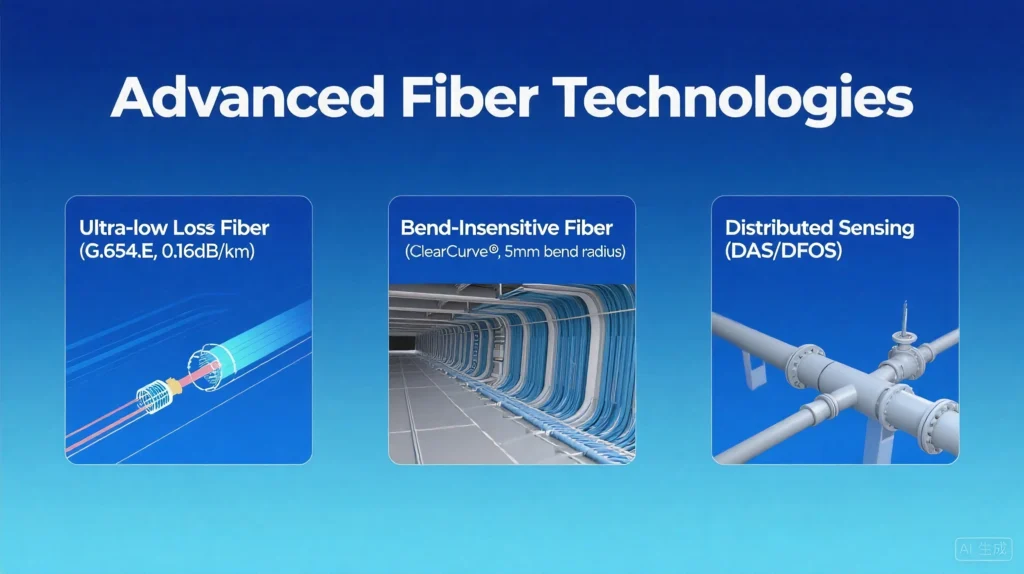

Advanced Fiber Technologies

Ultra-low loss (0.16dB/km), bend-insensitive (5mm radius) fibers & DAS/DFOS sensing enable high-performance rail networks.

Ultra-Low Loss & Bend-Insensitive Fiber

Recent advancements in fiber technology have transformed rail transit fiber infrastructure. Ultra-low loss single-mode fibers now achieve attenuation rates as low as 0.16-0.17 dB/km, which supports high-capacity, long-haul transmission across rail networks. Nexans introduced G.654.E fiber cables that enable data rates up to 600 Gbps over 2,000 km without regeneration. This performance reduces the need for repeaters and lowers operational costs for rail operators.

Bend-insensitive fiber has also seen significant improvements. Corning’s ClearCurve® portfolio demonstrates a minimum bend radius of 5 mm with attenuation below 0.4 dB/km. These fibers withstand tight bends and physical stress, making them ideal for dense trackside cabling and confined spaces within rail vehicles. Over 1.2 million kilometers of bend-insensitive fiber were deployed in 2023, reflecting widespread industry adoption.

Ultra-low loss fibers extend network reach and minimize signal degradation.

Bend-insensitive fibers maintain performance in complex transit fiber solution installations.

Hollow-core fiber technology promises even lower loss and reduced non-linearity, offering future benefits for wayside communication.

Fiber optic cables, including these advanced types, offer a lifecycle exceeding 20 years. Their resistance to wear and corrosion reduces maintenance needs. Immunity to electromagnetic interference ensures stable network performance in demanding rail environments.

Distributed Fiber Sensing Integration

Distributed fiber sensing (DFOS) systems are increasingly integrated into modern rail transit fiber networks. These systems inject light into the fiber and measure backscattered signals—Rayleigh, Brillouin, and Raman—to detect strain and temperature changes along several kilometers with high spatial resolution. DFOS enables early detection of defects such as cracks, leaks, and geometry changes in tracks.

Note: DFOS supports real-time monitoring and predictive maintenance, improving safety and operational efficiency.

Distributed Acoustic Sensing (DAS), a form of DFOS, provides continuous coverage for structural health monitoring, train tracking, and fault detection. DAS uses optical time domain reflectometry to monitor railroad conditions and operational speed. Machine learning algorithms analyze large datasets from DAS, enhancing maintenance accuracy and safety. These technologies help operators identify anomalies and estimate the remaining useful lifespan of infrastructure.

Technology | Application in Rail Transit Fiber | Benefit |

|---|---|---|

Ultra-Low Loss Fiber | Long-haul trunk lines | Reduced repeaters, lower costs |

Bend-Insensitive Fiber | Dense cabling, confined spaces | Robustness, minimal signal loss |

Distributed Fiber Sensing | Track monitoring, predictive maintenance | Early defect detection, improved safety |

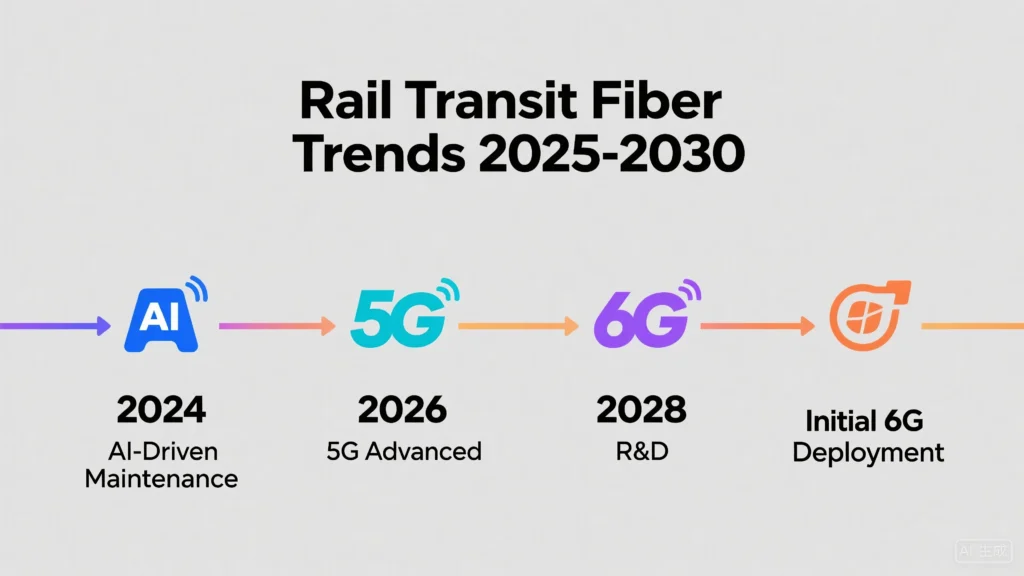

Rail Transit Fiber Trends 2025-2030

AI maintenance, 5G Advanced & 6G R&D (2028) drive next-gen rail fiber infrastructure.

AI-Driven Predictive Maintenance

Rail transit fiber infrastructure will experience rapid growth from 2025 to 2030, fueled by digital transformation and broadband industry innovation. Operators increasingly deploy distributed fiber optic sensors for continuous monitoring of trackside cabling, wayside communication, and transit fiber solution performance. These sensors enable real-time detection of faults, temperature changes, and vibration, supporting predictive maintenance strategies.

The broadband sector sees significant investment opportunities as federal funding and broadband funding drive rural buildouts and high-speed internet expansion. The June 2025 pilot program by Sensonic GmbH and the Chicago Transit Authority demonstrates how Distributed Acoustic Sensing technology enhances safety and reduces service disruptions. This trend reflects the broader move toward integrating AI and machine learning with fiber broadband infrastructure, optimizing maintenance schedules and minimizing downtime.

The economy benefits from improved reliability and reduced costs, while digital rail networks close the divide between urban and rural regions. Operators leverage technological advancements to support continuous infrastructure monitoring, ensuring robust telecommunications and broadband connectivity.

Operators who invest in AI-driven predictive maintenance gain a competitive edge in safety, operational efficiency, and cost control.

5G Co-Deployment & 6G Roadmap

The next phase of rail transit fiber trends centers on broadband buildouts that support 5G co-deployment and the development of a 6G roadmap. Key milestones include the release of 5G Advanced features, which introduce AI/ML support and tighter integration of terrestrial and non-terrestrial networks. The inclusion of Railway Mobile Radio in 5G Advanced enables vertical integration for rail communications. The 6G roadmap begins with the 3GPP Release 21 specification work, with workshops and study packages scheduled for 2025. Spectrum harmonization and sustainability remain priorities, aligning with global digital economy goals. Non-terrestrial networks, such as satellites and UAVs, extend coverage and resilience for rail transit fiber infrastructure. Fixed-mobile convergence and multi-access connectivity ensure seamless integration of wireline and wireless broadband networks. Federal money and bead funding continue to support investment in broadband expansion, bridging the digital divide and enabling high-speed internet expansion for rail transit systems.

Milestone/Feature Category | Description | Timeline/Notes |

|---|---|---|

5G Advanced (Release 18) | AI/ML support, energy efficiency, NTN integration | Early 2024 |

6G Specification Work | Start of 6G requirements | March-June 2025 |

Railway Mobile Radio | Vertical integration for rail | 5G Advanced |

Spectrum Harmonization | Coordination for NTN/terrestrial | WRC-27 (2027) |

Sustainability | Energy reduction, SDGs | Ongoing |

Fixed-Mobile Convergence | Seamless wireline/wireless | Ongoing |

High-Speed Rail Case Study

Laser interferometry, neural networks & armored cables solve vibration challenges in high-speed rail deployments.

Network Design & Implementation

High-speed rail projects demand a robust network to support safety, signaling, and passenger connectivity. Engineers focus on several design considerations to ensure reliable performance:

Robust sensing capabilities, such as laser interferometry, detect vibrations and monitor structural health along extensive rail sections.

Long-distance signal detection enables monitoring over more than 100 kilometers, providing comprehensive coverage for the entire network.

Environmental resilience ensures the network operates through seasonal changes, rainstorms, and seismic events.

Integration with existing telecom fiber cables within cable ducts reduces installation complexity and leverages current infrastructure.

Advanced data processing, including neural networks, allows real-time localization and classification of train-induced vibrations.

Compliance with safety and regulatory requirements remains essential for all network components.

Engineers often face challenges like high initial costs, complex installation logistics, and the need for regular maintenance. In dense urban areas, excavation and conduit installation can increase costs and extend project timelines. Collaboration among governments, industry, and stakeholders helps streamline policies and accelerate adoption. Network upgrades must address these challenges while maintaining strict safety standards.

Lessons Learned: Vibration Isolation

Vibration isolation stands out as a critical lesson from recent high-speed rail deployments. Teams discovered that environmental factors, such as heavy train loads and variable weather, can impact network stability. To address this, they implemented several strategies:

Use of armoured fiber cables and protective sheaths to shield the network from physical damage.

Deployment of hybrid fiber-copper networks in areas lacking fiber-grade connectivity, reducing costs and speeding up installation.

Adoption of hardened fiber-optic switches and rapid deployment solutions to extend network reach and provide reliable power.

Implementation of cyber-hardened security protocols to protect the network from digital threats.

A table summarizing key strategies:

Challenge | Solution |

|---|---|

Vibration & Physical Stress | Armoured cables, protective sheaths |

Connectivity Gaps | Hybrid fiber-copper networks |

Deployment Speed | Rapid deployment solutions |

Cybersecurity | End-to-end encryption, network segmentation |

Tip: Proactive vibration isolation and regular maintenance ensure the network remains resilient, supporting both safety and operational efficiency in high-speed rail environments.

Rail transit fiber advancements in 2025 drive remarkable growth in vibration resistance, signaling, and operational reliability. New technologies such as AI-powered maintenance, 5G integration, and cleantech solutions fuel this growth, supported by strategic funding and sustainability initiatives. Stakeholders see growth in resilient, eco-friendly networks through modular designs, cybersecurity, and predictive analytics. These trends position rail transit fiber as a foundation for future-ready, efficient, and sustainable rail systems, ensuring continued growth across global markets.

Fiber Optic Termination Boxes

Fiber Optic Termination Boxes Fiber Optic Splice Enclosures

Fiber Optic Splice Enclosures Fiber Patch Panels

Fiber Patch Panels PLC Splitters

PLC Splitters Fiber Optic Pigtails

Fiber Optic Pigtails OTDR Launch Cables

OTDR Launch Cables Fiber Optic Adapters

Fiber Optic Adapters Fiber Optic Patch Cords

Fiber Optic Patch Cords